Laboratory pressure reactor system - easy operation for heavy pressure vessels

Reactor volume: 0.5 to 20.0 liter

Pressure: -1 (FV) to +60 / 200 bar

Temperature: -20 °C to +250 °C

Material: stainless steel, Hastelloy®, glass-lined steel

Other materials, pressures & temperatures are available

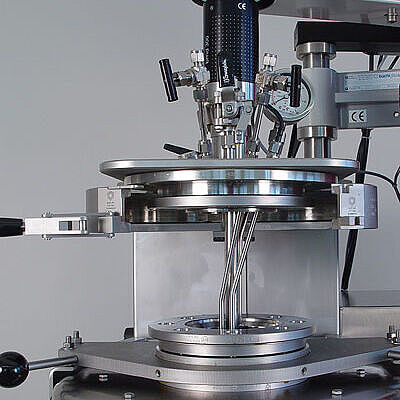

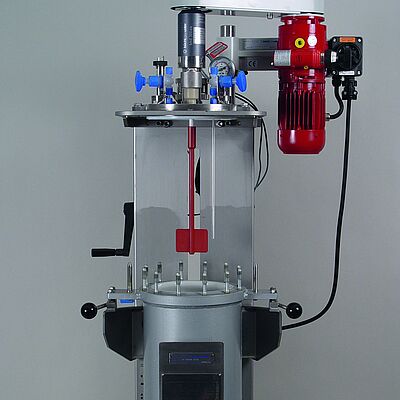

This multipurpose pressure reactor system is designed for the use of large steel pressure vessels. The hydraulic vessel lift with tilt function makes opening and closing as well as cleaning of the vessel very easy. Safety features guarantee safe reactions under pressure.

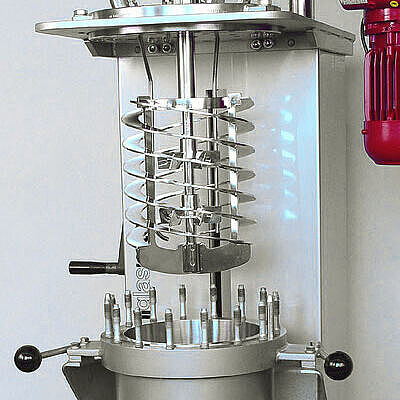

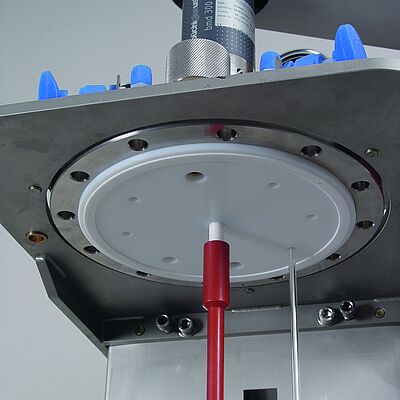

The stainless steel or Hastelloy® reactors ensure high resistance against acids. Visual process control and monitoring is also possible under high pressure by using steel pressure vessels with sight glasses. Various low to high torque magnetic drives ensure efficient mixing and stirring low to high viscosity process media as well as excellent heat transfer.

The modular setup of the kiloclave® system allows changing or upgrading for new tasks at any time.

A wide range of accessories for feeding of liquids, solids, gas, a fast action closure device and others like catalyst baskets etc. are available – talk to us to define the right setup for your specific need.