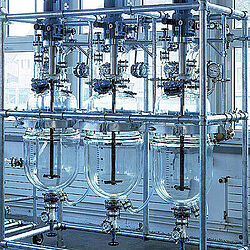

Mobile and stationary units

Mixing vessels (jacketed glass vessel): 10, 30, 50, 100 liter

Mixing vessels (non-jacketed glass vessel): 10, 30, 50, 100, 200 liter

Storage tanks (non-jacketed glass vessel): 10 to 400 liter

Pressure: -1.0 (FV) to +0.5 bar

Temperature: -60 °C (-90 °C) to +150 °C (200 °C)

Material: Borosilicate glass 3.3, PTFE, PFA, ETFE

Other setups are available

Mixing vessels are frequently used for stirring, dissolving, mixing, extraction and other processes in kilo labs and pilot plants. Jacketed glass reactors permit heat exchange for better dissolving and crystallization.

Mobile mixing vessels can be transported with their content for further processing. They can also be equipped with condensers for vacuum distillation and operated as a reactor. Connection to Buchi reactors or other equipment is usually done with camlock adapters and flexible hoses.

Glass tanks are used in distillation glass overheads as feeders and receivers. Such vessel are normally graduated, sometimes coated with Buchi glass protect coating to protect the glass surface against scratches. Antistatic coating according to ATEX is available.

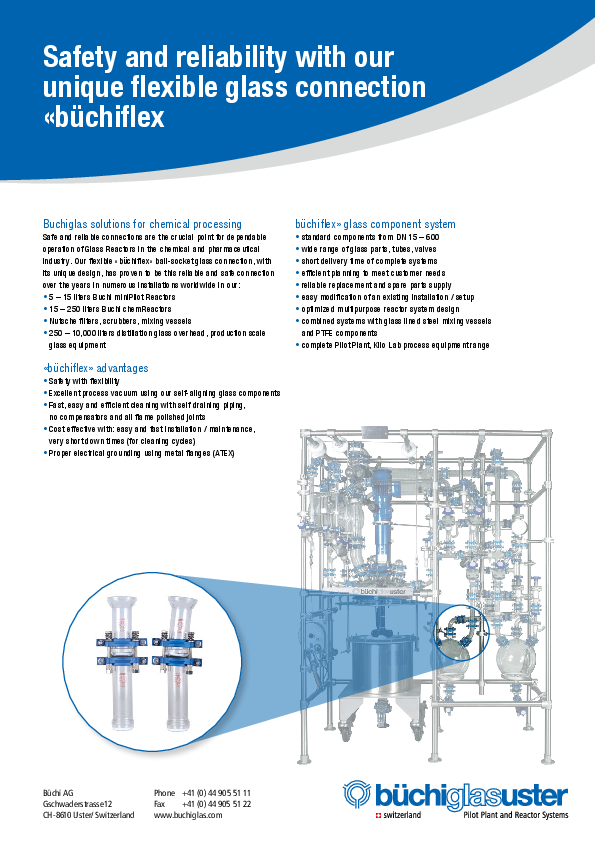

Depending on the application, glass tanks, mixing vessel and reactors vary a lot in their design. A selection of standardized vessels including info on the configuration can be found in the buchiflex glass catalog about glass components.